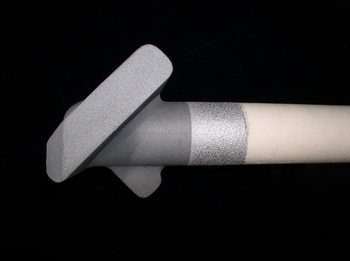

Platinum coated partitions and blocks prolong production periods of the aggregate and eliminate deterioration of the structure of the materials in the most exposed parts of the furnace. Prolonged service life significantly reduces interruptions in production that arise from frequent replacements, thus improving cost and production uptime. Other possibilities for platinum coating include application on devices that are exposed to a combination of aggressive conditions during melting and processing – i.e. bubble jets and stones, melting pots for melting aggressive glass, and more. This improvement leads to a significant increase in quality of production and prolonged service life of the entire aggregate.